Discover the solutions in the world of lithium battery testing.

Do you fear for your safety when testing lithium batteries? Discover the solutions applied by Ineltec in the world of lithium batteries.

Lithium-ion batteries have some risk of fire and explosion. Due to their high electricity density, they can ignite spontaneously under certain high or low temperatures, or become unstable and explode when heated.

Currently, due to several accidents on worldwide such as fires TESLA vehicles, testing procedures and recommendations have been established in the automotive market and safety systems have been included in these batteries.

During tests with climatic chambers, overcharging or malfunctions of the batteries can occur, which can even lead to an explosion. Depending on the size of the battery and its energy, the possible failures and danger during the test increase. Knowing the potential effects, is it essential to have maximum safety in the laboratory. For this reason, different levels of safety, known as Hazard Levels, have been defined.

The Hazard Levels represent the level of risk that assume the different types of tests may have. If we want to do a test on a lithium battery over 80°C of temperature, we can consider that it may explode, being at a high Hazard Level. If we want to test the batteries between 20° to 40°C, to see their cyclic degradation, as they are out of the margin of overcoming, we consider that they have a low Hazard level.

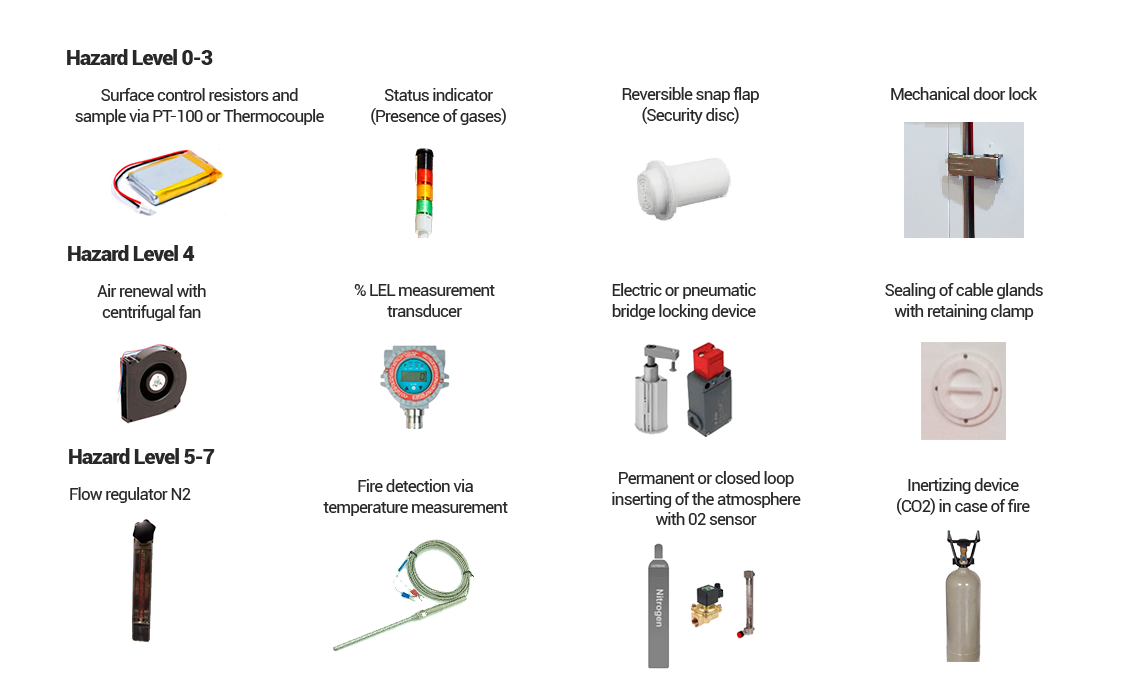

To define these levels, we can see from the table that there are seven levels, with seven being the maximum danger and zero being the minimum or none. It must make a difference between the two parts. The first one would be Hazard levels 0 to 4 (below level 4), where there is no risk of explosion, so there is no combustion. And from 5 to 7, there is the combustion, material that can be shot out and there is a possibility of explosion.

Ineltec's solution to all the points mentioned above is as follows:

We adapt our climatic or thermal chambers with safety seals, externally made electric cable, pressure relievers, and bursting discs (in case the pressure reaches too high a point), the temperature status of the sample is constantly monitored as well as the temperature status of the resistors. Volatile and hydrogen compounds in the atmosphere inside the chamber are continuously monitored in case it is necessary to immunise the chamber, the oxygen content inside the chamber is also monitored and a nitrogen input is provided to lower the oxygen rate inside the chamber if required.

¿Teme por su seguridad en el momento de realizar ensayos de baterías de litio? (2022). Retrieved 1 April 2022, from https://www.youtube.com/watch?v=4YGis3kQ_us