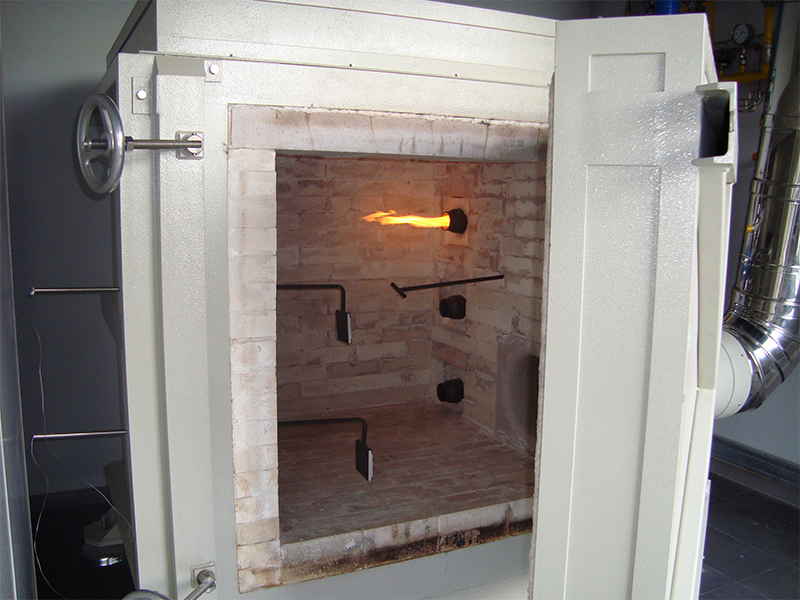

Cubic furnace

fire resistance testing of materials used in building construction.

Cubic furnaces are designed and manufactured to assess how long a construction element maintains its function, integrity and stability. It is related to applying safety criteria to ensure evacuation in case of fire.

These furnaces are used to research new products, dampers, fire dampers, electrical conduits, intumescent paints, extractors, etc. The test tube can be horizontal or vertical, depending on the material to be tested.

At Ineltec, we design and manufacture customised equipment according to customer specifications, modifying or extending standard features.

UNE 23093:1998, UNE EN 1363:2000, UNE-EN 1364 UNE-EN 13501 UNE-EN 1365 UNE-EN 1366 UNE-EN 1634 UNE-EN 14600 CEN/TS 13381 UNE-ENV 13381 UNE-ENV 14135 UNE-ENV 14470 UNE-ENV 1634 UNE-ENV 81-58 UNE-ENV 12101 ASTM E119, among others.

According to the UNE-EN 13501 standard, once the fire resistance test has been carried out, excluding ventilation installations, materials are classified according to the data obtained:

- R: Maintains load-bearing capacity

- E: Maintains integrity

- I: Maintains thermal insulation

- W: Complies with radiation criteria

- M: Maintain the mechanical actions

- C: Complies with mechanical seal requirements

- S: Complies with smoke-tightness requirements

- P/HP: Continuity of electrical signal

- K: Fire protection capability

Main Structure: This structure is covered on the inside with a 4 mm thick steel plate. The structures are fully assembled with all component elements, including burners, tubes, transducers, etc. as well as the refractory insulation materials. All metal parts are coated with a heat-resistant anticorrosive prime, the exterior is painted.

- Sighting glass: 2 sighting glasses of 100x100 mm made of high-temperature resistant rock crystal can be installed (on request).

- Sample locking system: The sample locking system is made of four centring bearings. Sealing is ensured by a high-temperature ceramic fibre profile which is installed all around the furnace.

Isolation: The thermal insulation of the furnace is achieved by a combination of three elements: Ceramic fibre inner lining, the second layer of insulation using refractory bricks and the third layer of refractory bricks of ISO-170/ASTM-33 classification.

The touch screen PC has the PROCAM-WIN installed. It is easy and intuitive software which performs programming tasks, acquisition, records, control and analysis of the results.

- Manual or automatic programming

- Possibility of programming date and time of the test

- It allows recording notes during the tests

- Different access levels

- Maximum 11 operators

- Display and recording of tests in a graphical or tabular table

- Export to excel or similar

- Setting of minimum and maximum alarms for temperature and humidity for each section

- It includes recording screen, incidences and maintenance.