Pulsating pressure chambers

they are designed according to the customer specifications

Pulsating pressure climatic chambers are combined test chambers, which are characterized by the fact that they are designed to be adapted to a test bench.

They have the capacity to generate air, gas or liquid flow with fluid temperature and ambient temperature control, with leak detection. They can be used in all industrial sectors and are designed for testing radiators, condensers, evaporators, water/glycol ducts, etc.

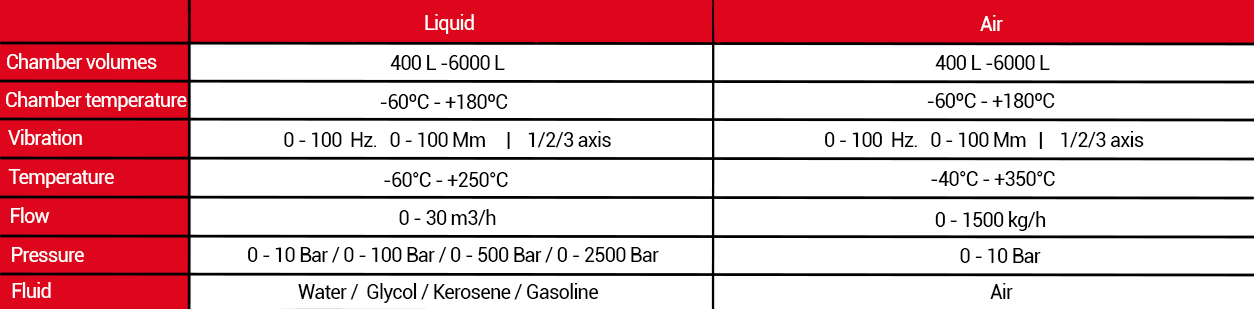

It is also possible to combine the pulsating air or liquid pressure chamber with other parameters such as temperature or vibration.

PSA: B2226142, BB226160, B226120; BMW: QV17006, Renault: 36-06-008, Ford: ESDG93-8260-AA, GM: GMV14329

Exterior: It is made of white lacquered aluminium sheet.

- Access door: Flexible double silicone gasket, sized according to chamber volume.

- Viewing window: Tempered Multi-crystal, 10 vacuum sealed glass panels, size according to chamber volume.

- Mobility: 4 swivel wheels with 2 braking devices or 4 height-adjustable legs.

Interior: It is made of AISI-304 stainless steel.

- Interior lighting: Fluorescent with interior projection.

- Access holes 1 side wall hole Ø 50mm (others on request)

- Accessories: 2 sample-holding trays made of perforated stainless steel plate, adjustable in height. Max weight 50 Kg (others on request)

Insulation

- Density 41 kg/m3

- Coefficient of thermal conductivity: 0,0136 Kcal/m. hºC

- Coefficient of thermal transmission

- Completely waterproof and resistant to corrosive attack by acids and alkalis

The touch screen PC has the PROCAM-WIN installed. It is easy and intuitive software which performs programming tasks, acquisition, records, control and analysis of the results.

- Manual or automatic programming

- Possibility of programming date and time of the test

- It allows recording notes during the tests

- Different access levels

- Maximum 11 operators

- Display and recording of tests in a graphical or tabular table

- Export to Excel or similar

- The setting of minimum and maximum alarms for temperature and humidity for each section

- It includes recording screens, incidences and maintenance.