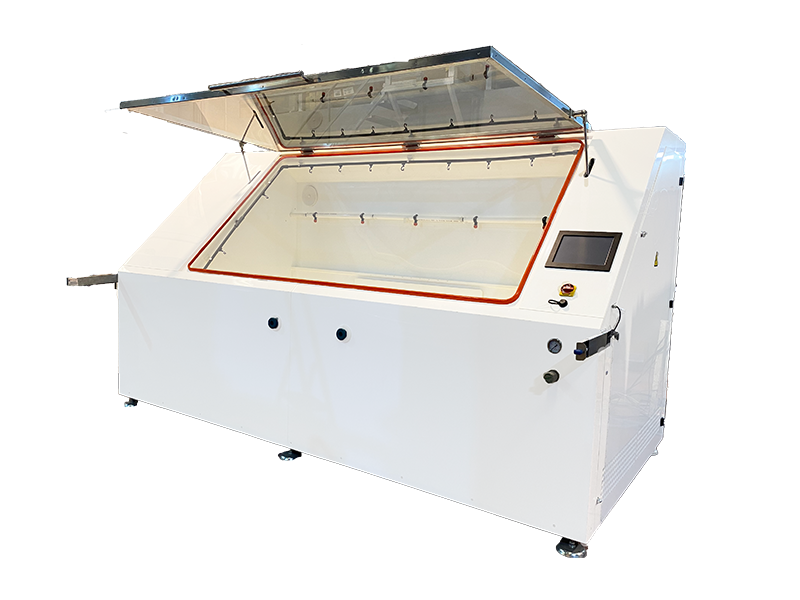

Cyclic corrosion chamber

With the ability to perform climatic (hot-cold), salt spray and saturated humidity tests.

Cyclic corrosion chambers are designed to perform accelerated corrosion tests. through alternative cycles and reproduce a redundant set of environmental conditions, where humidostatic, saline and climatic stages are combined.

Its temperature range can be from +15°C or -20°C up to 60°C and it has three possible volumes, 400, 1000 and 2000 litres. They are mainly used for "Automotive" tests according to international standards.

In Ineltec, we design and manufacture tailor-made equipment according to specifications, modifying or extending standard features.

DIN 50014 / ISO 6270-2 / UNE-EN ISO 6270-2 / DIN ISO 6270-2 / DIN ISO 9227 / UNE-EN ISO 9227:2007 / EN ISO 9227:2007 / ASTM B117 / NES M-007 (NISSAN) / NES 21481 NDS00 (NISSAN) / P-VW 1220 (VOLKSWAGEN) / D17-11686 (RENAULT), among others.

Exterior: Made of white anti-corrosive polypropylene. Resistant, easy to clean and maintain.

- Cabinet base: 6 height-adjustable legs

- Top cover: in the form of a canopy, made of transparent polyethylene. Opening and closing by pneumatic cylinders. It allows the samples to be observed during a test.

Interior: Made of polypropylene inert to corrosion.

- Support systems: Set of 6 support bars to support the parts to be tested (other on request).

Isolation: By Armaflex blanket

Dimensions: (HxWxL)

| Volume | 400 L | 1000 L | 2000 L |

| Inside Dimension | 800 x 1068 x 550 | 800x1500x900 | 920 x 2134 x930 |

| Outside Dimension | 1525 x 2240 x 1300 | 1525 x 1500 x 900 | 1700 x 3600 x 162 |

Approximately, as it depends on the temperature range, the external dimension may be larger.

The touch screen PC has the PROCAM-WIN installed. It is easy and intuitive software which performs programming tasks, acquisition, records, control and analysis of the results.

- Manual or automatic programming

- Possibility of programming date and time of the test

- It allows recording notes during the tests

- Different access levels

- Maximum 11 operators

- Display and recording of tests in a graphical or tabular table

- Export to excel or similar

- The setting of minimum and maximum alarms for temperature and humidity for each section

- It includes recording screens, incidences and maintenance.